As businesses throughout industries seek out ground breaking ways to minimize their environmental footprint, custom molded pulp packaging has emerged as a sport-shifting Alternative. giving a versatile and sustainable alternative to standard packaging resources, molded pulp products are crafted applying renewable sources like recycled paper and agricultural byproducts. This eco-pleasant packaging not only allows models meet growing purchaser demand from customers for sustainability but additionally provides dependable, customizable, and price-efficient protection for a wide array of items.

Table of contents:

Designing custom made Packaging: From Cup Lip Molds to Unique product or service Inserts

benefits of Customization: Branding Opportunities and Improved item security

circumstance scientific studies: prosperous Implementations of personalized Molded Pulp in Intercontinental Markets

planning tailor made Packaging: From Cup Lip Molds to one of a kind products Inserts

the whole world of packaging has increasingly embraced eco-welcoming choices, and custom made molded pulp packaging is on the forefront of this change. built to Incorporate sustainability with functionality, these remedies offer worldwide models the chance to enhance equally their environmental impression and merchandise overall performance. a person exceptional illustration of this innovation is Dwellpac’s precision-engineered aluminum cup lid molds, which underscore the likely of molded pulp merchandise. These molds allow brands to obtain unparalleled consistency, generating leak-proof, biodegradable cup lids that meet the rising demand for sustainable packaging. By giving specialist customization, corporations like Dwellpac empower world businesses to align with eco-friendly initiatives and custom molded pulp packaging reduce squander. From cup lip molds to distinctive merchandise inserts, the look method makes sure each individual merchandise is exactly personalized to its practical specifications. This awareness to detail not just safeguards goods during transit but in addition opens up branding opportunities, as custom made styles enable organizations to encapsulate their brand ethos in eco-friendly packaging.

benefits of Customization: Branding alternatives and Improved merchandise Protection

The advantages of customization in molded pulp packaging prolong outside of aesthetics. whilst branding prospects make it possible for organizations to build a more robust connection with consumers, the inherent protective characteristics of these models guarantee item security throughout offer chains. products and solutions like Dwellpac’s cup lid molds display how eco-helpful packaging procedures can sustain sturdiness and operation with out compromising on sustainability. Customization also supports scalability for manufacturers, permitting them to successfully cater to bulk orders when protecting uniform high quality throughout all packaging remedies. By leveraging resilient resources like aluminum and CNC-machining processes, tailor made molded pulp packaging remedies are crafted to resist high-quantity generation with out sacrificing precision. This results in the two Expense-performance and environmental duty, which makes it a acquire-win for world-wide makes.

situation research: Successful Implementations of custom made Molded Pulp in Worldwide Markets

circumstance research from Worldwide marketplaces affirm the developing importance of personalized molded pulp answers. foremost corporations throughout a variety of industries have adopted customized molded pulp products to deal with their exclusive wants. As an example, a worldwide beverage brand lately built-in Dwellpac’s tailor made cup lip molds to make certain its takeaway cups used leak-proof, biodegradable lids. This change not simply Increased the customer encounter by presenting sustainable packaging but in addition aligned the model’s operations with worldwide eco-pleasant expectations. Another instance is usually a luxury electronics producer that used tailor made inserts made out of molded pulp items to guard fragile gadgets throughout shipping while boosting the unboxing expertise for its buyers. These implementations mirror the versatility and effectiveness of molded pulp methods in Assembly complex business desires with a concentrate on sustainability. Custom eco-friendly packaging has undeniably grow to be an essential Device for makes aiming to prosper in today’s environmentally acutely aware marketplace landscape.

In summary, the shift toward tailor made eco-friendly packaging methods highlights a significant transformation in how organizations embrace sustainability. By adopting tailor-made, environmentally liable models, makes can lower their ecological footprint although interesting to contemporary, eco-conscious people. customized sustainable packaging enhances model id, fosters shopper loyalty, and positions firms for long-expression results inside a aggressive, eco-friendly-pushed sector. selecting eco-helpful packaging isn’t simply a trend — it’s a requirement for enterprises aiming to lead in sustainable innovation.

Scott Baio Then & Now!

Scott Baio Then & Now! Val Kilmer Then & Now!

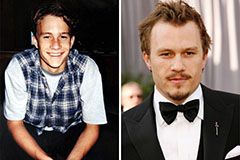

Val Kilmer Then & Now! Heath Ledger Then & Now!

Heath Ledger Then & Now! Jennifer Love Hewitt Then & Now!

Jennifer Love Hewitt Then & Now! Burke Ramsey Then & Now!

Burke Ramsey Then & Now!